Add to Cart

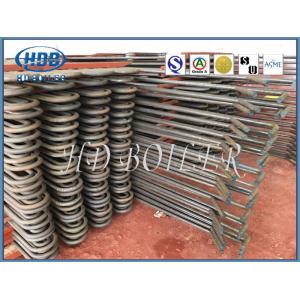

Carbon Steel Waste Heat Exchange Flue Gas Cooler for drying or cooling usage

Product Introduction

Specifications

| Fuel: | Flue Gas | Dust Treatment: | Sonic Blower / Steam Blower |

|---|---|---|---|

| Pressure: | Low Pressure | Condition: | New |

| Function: | Wate Heat Recovery | Port: | Shanghai |

Details

Efficiency

Flue gas condensation may cause the heat recovered to exceed the Lower Heating Value of the input fuel, and thus an efficiency greater than 100%. Since historically most combustion processes have not condensed the fuel, usual efficiency calculations assume the combustion products are not condensed. This assumption is implicit when basing calculations on the Lower Heating Value. A more rigorous approach would be to base efficiency calculations on the Higher Heating Value, which typically results in efficiencies less than 100%.[citation needed]

Should the flue gases be cooled below 25 °C (77 °F), even efficiencies based on the Higher Heating Value may exceed 100%, since typical heating value definitions assume that all heat is released when combustion products are cooled to somewhere between 15.56 °C (60.01 °F) and 25 °C (77 °F).

Conclusion

To sum up, the following items have to be taken into account when designing a flue-gases cooler:

Kind of fluid.

Dust content.

Maintenance and cleaning works.

Connection of the equipment with the rest of the plant.

Depending on the above mentioned factors, different technical solutions may be applied which will go through the adoption of an arrangement:

Vertical/Horizontal.

Modular (with only one or many fans).

One or more steps.

Packing

Company Information

Established in 1985,Zhangjiagang Hua Dong Boiler Co.,Ltd.(trading as HD Boiler),produces power plant; industrial; waste heat; waste incineration; biomass; organic heat carrier and electric steam boilers. Coupled with a comprehensive range of heating surfaces, HD Boiler brings to the market a unique service including boiler design , fabrication, installation, maintenance and replacement of boiler pressure parts.

1. Fabrication area of 200,000 square meters

2. 150 Engineers

3. 600 Coded welders

4. 60 Licensed Inspectors(NDT Level-III instructors)

5. Class-A Licenses for Design and Manufacture Boiler

6. ISO 9001:2008 Quality System

7. ASME Certificate of Power Boilers

8. ASME 'S','U' and NB stamp authorization